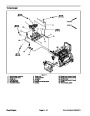

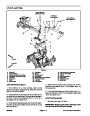

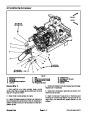

Removal (Fig. 56)

Park machine on a level surface, lower cutting

decks, stop engine, apply parking brake and remove

key from the ignition switch.

Installation (Fig. 56)

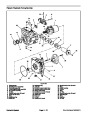

1.

1. If fittings were removed from wheel motor, lubricate

and place new O--rings onto fittings. Install fittings into

motor ports and tighten fittings (see Hydraulic Fitting

Installation in the General Information section of this

chapter).

2.

Installing Hydraulic System Components at the begin-

ning of the Service and Repairs section of this chapter.

Read the General Precautions for Removing and

2. Lightly oil new O--ring (item 9) and place on wheel

motor flange.

3.

To prevent contamination of hydraulic system during

motor removal, thoroughly clean exterior of motor, hy-

draulic tubes and fittings.

3. Positionwheelmotortobrakeassemblymakingsure

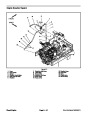

that case drain port is above supply line ports (Fig. 57).

4.

To allow easier access to hydraulic tube fittings at

4. Align splines on motor shaft and splined brake shaft

in brake assembly. Slide motor into brake assembly.

wheelmotor,removepinthatsecuresliftcylindertofront

deck lift arm and lower front of lift cylinder (see Front

Deck Lift Cylinder Removal in this section).

5.

Secure motor to brake and planetary assemblies

with two (2) cap screws and flat washers. Torque cap

5.

loosen fittings that are at other end of tubes to allow

tubes to be shifted for wheel motor removal.

Disconnect hydraulic tubes from wheel motor. Also,

screws from 75 to 85 ft--lb (102 to 115 N--m).

6.

Remove plugs from hydraulic lines and fittings. At-

tach hydraulic tubes to wheel motor and then tighten all

tube fittings (see Hydraulic Hose and Tube Installation

in the General Information section of this chapter).

6.

and fittings to prevent contamination.

Put caps or plugs on disconnected hydraulic lines

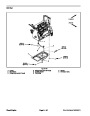

IMPORTANT: Before loosening fasteners, support

wheel motor to prevent motor fromfalling during re-

moval.

7. Fill reservoir with new hydraulic fluid as required.

2

1

7.

Removetwo(2)capscrews andflatwashers thatse-

cure front wheel motor to brake and planetary assem-

blies.

UP

8.

Slide front wheel motor from brake assembly and re-

move from machine.

9.

Remove and discard O--ring from between wheel

motor and brake assembly.

3

3

10.If

necessary, remove fittings from wheel motor and

discard fitting O--rings.

Figure 57

1.

2.

Wheel motor backplate

Case drain port

3. Supply line port

Groundsmaster 5900/5910

Page 4 -- 79

Hydraulic System

Product Specification

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 5900, Toro Groundsmaster 5910 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |