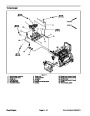

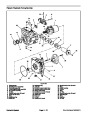

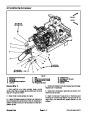

Removal (Fig. 9)

Park machine on a level surface, lower cutting

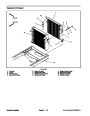

9/16”

hole

3”

x 12” (3/8” to 1/2” thick) plate steel

1.

decks, stop engine, apply parking brake and remove

key from the ignition switch.

2.

Deck in Chapter 8 -- Cutting Decks).

Remove wing deck from lift arm (see Wing Cutting

1/2”

-- 13 UNC bolt

Flat washer

3.

hub (see Wing Deck Impact Arm Assembly in this sec-

tion).

Remove wing deck impact arm assembly from pivot

1”

to 1 1/8”

4.

Remove joint yoke and cutting deck connection from

lift arm (Fig. 12):

A. Support cutting deck connection to prevent it

from falling.

B. Remove cotter pin, slotted hex nut, hardened

washer and thrust washers from joint yoke shaft.

C. Lower joint yoke, cutting deck connection and

wing deck impact arm assembly from lift arm.

Use hammer to remove

pivot shaft from lift arm

5.

inderpin(item5)toliftarm.Slidecylinderpinfromliftcyl-

inder and lift arm. Separate lift cylinder from lift arm.

Remove cap screw and flange nut thatsecure liftcyl-

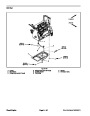

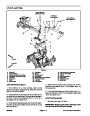

Figure 10

6.

24)

Remove cap screw (item 23) and flat washer (item

from lift arm pivot shaft.

5

4

1

7.

Slide wing deck impact arm pivot hub and thrust

washer (item 29) from lift arm pivot shaft.

2

8.

Drive out roll pin (item 22) that retains lift arm pivot

shaft to frame. Discard roll pin.

3

9.

Support lift arm to prevent it from shifting or falling.

4

Pull lift arm pivot shaft from lift arm and frame. Locate

and remove thrust washer (item 29) during pivot shaft

removal.

2

NOTE: If pivot shaft is difficult to remove, fabricate a

puller asshowninFigure10.Attachpuller toendofpivot

shaft with the pictured bolt and flat washer. Drive pivot

shaft from lift arm and frame with hammer.

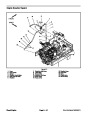

Figure 11

1.

2.

3.

Lift arm (LH shown)

Flange bushing

Grease fitting

4.

5.

Straight bushing

Grease fitting

10.Remove

lift arm from machine.

3. Position lift arm to frame with thrust washer (item 29)

properly placed between rear of lift arm pivot hub and

frame. Slide pivot shaft into frame, thrust washer and lift

arm until roll pin holes in pivot shaft and frame align.

11.

If necessary, press bushings from lift arm (Fig. 11).

Thoroughly clean lift arm bores.

Installation (Fig. 9)

4. Install new roll pin (item 22) to secure lift arm pivot

shaft to frame.

1.

If bushings were removed from lift arm, press new

bushings into lift arm bores. Make sure that bushings

are pressed fully to lift arm surface.

5. Slide thrust washer (item 29) and then wing deck im-

pactarmpivothubontopivotshaft.Makesurethatthrust

washer is between frame and pivot hub.

2.

Apply anti--seize lubricant to lift arm pivot shaft.

Groundsmaster 5900/5910

Page 7 -- 13

Chassis

Product Specification

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 5900, Toro Groundsmaster 5910 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |