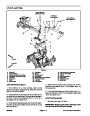

Traction Circuit: Low Speed

A variable displacement, bi--directional piston pump is

directly coupled to the engine flywheel to provide hy-

draulic flow for the traction circuit. The piston pump

swash plate movement is controlled by an electronic

proportional servo assembly.Pushing the traction pedal

rotates a potentiometer that sends a signal to the ma-

chine TEC--5002 controller. The controller in turn sends

a corresponding PWM (Pulse Width Modulation) output

signal to the hydrostat electronic control to rotate the

pumpswashplateaccordinglytocontrolthepump’sout-

put. The oilfromthehydrostat isdirected tothefrontand

rear wheel motors through the traction, 4WD and trac-

tion flush control manifolds.

Forward Direction

With the low speed range selected and the traction ped-

al pushed in the forward direction, oil from the hydrostat

port MB passes through the traction control valve (see

TractionCircuit:TractionControlinthissection). Oilflow

fromtraction control valve portM1 drives thefrontwheel

motors in the forward direction and then returns to the

hydrostat. Oil flow from traction control valve port M2 is

routed to the P1 port of the 4WD control valve where it

is directed to the PD1 cartridge and out of the manifold

to drive the rear wheel motors in the forward direction.

Oil returning from the rear motors re--enters the 4WD

control valve at the M2 port. Flow passes through the

PD2 cartridge, through the CV check valve, out valve

port P2 and back to the hydrostat.

Operating pressure on the high pressure side of the

closed loop traction circuit is determined by the amount

of load developed at the fixed displacement wheel mo-

tors. As the load increases, circuit pressure can in-

crease to relief valve settings: 4330 PSI (299 bar) in the

forward direction and 5330 PSI (368 bar) in reverse. If

pressure exceeds the relief setting, oil flows through the

relief valve to the low pressure side of the closed loop

traction circuit.

To keep the traction circuit oil properly cooled, a flush

valveisincorporatedintothetractioncircuit.Wheninthe

forward direction, the flush valve spool is shifted by for-

ward pressure and allows a small amount of hydraulic

fluidtobleedoffforcoolingoftheclosedlooptractioncir-

cuit. The charge system replenishes oil that is bled from

the traction circuit due to the flushing valve operation.

Traction circuit pressure (forward and reverse) can be

measured at test ports located on the hydrostat.

When going down a hill, the tractor becomes an over--

running load that drives the wheel motors. In this condi-

tion, the rear wheel motors could lock up as the oil

pumped from the motors increases pressure as it re-

turns to the hydrostat. To prevent wheel lock up, an ad-

justable relief valve (RV) in the 4WD control valve

reduces rear motor pressure created in down hill, dy-

namic braking conditions.

The traction circuit provides operation in either low

speed (four wheel assist) or high speed (two wheel

drive).

The traction pump and wheel motors use a small

amount of hydraulic fluid for internal lubrication. Fluid is

designed to leak across the pump and motor parts and

into the component case drain. This leakage results in

the loss of hydraulic fluid from the closed loop traction

circuit that must be replaced. The charge circuit is de-

signed to replace this traction circuit leakage.

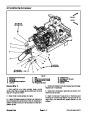

Reverse Direction

The traction circuit operates essentially the same in re-

verselowspeedasitdoesintheforward direction.How-

ever, the flow through the circuit is reversed. Oil flow

from the hydrostat port MA is directed to the front wheel

motors and to 4WD control valve port P2. Oil to the front

wheel motors drives them in the reverse direction and

then returns to the hydrostat through the traction control

valve.Oilflowtothe4WDcontrolvalveflowsthroughthe

PR pressure reducing valve which limits the down

stream pressure to the rear wheel motors to 650 PSI(45

bar) so the rear wheels will not scuff the turf. This re-

duced pressure flow passes through the PD2 cartridge

andoutportM2totherearwheelmotors.Return oilfrom

the rear motors re--enters the 4WD control valve at port

M1, flows through the PD1 cartridge, exits the manifold

at port P1 and returns to the hydrostat through the trac-

tion control manifold.

Thegearpumpsection(P3)thatsuppliesoiltothesteer-

ing, lift and cooling fan circuits, also provides charge oil

for the traction circuit. The gear pump is driven directly

off the traction pump. It provides a constant supply of

charge oil to the traction circuit to make up for oil that is

lost to internal leakage in the traction pump and wheel

motors. Charge pump flow is directed through the

charge oil filter before entering the hydrostat. This filter

has a bypass valve that allows charge oil flow to the

closed traction loop if the filter becomes plugged.

The charge pressure is limited to 330 PSI (22.8 bar) by

a relief valve located in the hydrostat. Charge pressure

canbemeasured atthecharge pressure testport (G) on

the hydrostat.

When in the reverse direction, the flush valve spool re-

mains in the unshifted position to prevent any traction

circuit fluid loss.

Groundsmaster 5900/5910

Page 4 -- 13

Hydraulic System

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 5900, Toro Groundsmaster 5910 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)