Charge Hydraulic System

NOTE: When initially starting the hydraulic system with

new or rebuilt components such as motors, pumps or lift

cylinders, it is important that the hydraulic system be

charged properly. Air must be purged from the system

and its components to reduce the chance of damage.

1

IMPORTANT: Change hydraulic oil filter whenever

hydraulic components are repaired or replaced.

2

1.

Position machine on a level surface. Remove key

from the ignition switch.

2.

Make sure all hydraulic connections, lines and com-

ponents are tight.

3.

taminated, flush and refill hydraulic system and reser-

voir (see Flush Hydraulic System in this section).

Ifcomponentfailurewassevereorthesystemiscon-

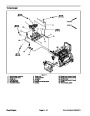

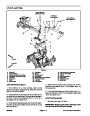

Figure 47

1.

Engine ECM

2.

Power connector

4.

Make sure hydraulic reservoir is full. Add correct hy-

draulic oil if necessary.

2

IMPORTANT: Before unplugging the wire harness

power connector from the engine ECM, make sure

that the ignition switch is in the OFF position and

the key is removed from the switch. If the harness

power connector is removed from the engine ECM

while electrical power is on, the ECM may be dam-

aged.

5.

Make sure that the ignition switch is OFF and the key

is removed from the switch. Unplug the wire harness

power connector from the engine ECM to prevent the

engine fuel solenoid from being energized (Fig. 47).

Thiswillkeeptheenginefromstartingwhilecrankingthe

engine.

1

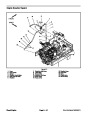

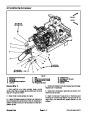

Figure 48

1.

Hydrostat

2.

Charge test port

6.

Connect a 1000 PSI (70 Bar) pressure gauge onto

charge pressure test port fitting on hydrostat (Fig. 48).

IMPORTANT: Before connecting the wire harness

power connector to the engine ECM, make sure that

theignitionswitchisintheOFFpositionandthekey

is removed from the switch. If the harness power

connector is plugged into the engine ECM while

electrical power is on, the ECM may be be damaged.

7.

Make sure traction pedal is in the neutral position.

TurnignitionkeyswitchtoSTARTandengagestarterfor

thirty (30) seconds to prime the traction and gear

pumps. Wait two (2) minutes to allow the starter to cool

and then repeat this step again.

10.Connect

gine ECM (Fig. 47).

thewireharnesspowerconnectortotheen-

8.

charge pressure test port indicates that pressure in the

charge circuit is increasing.

Repeat step 7 until the pressure gauge attached to

11.

Disconnect pressure gauge from charge pressure

test port (Fig. 48).

9.

Make sure that the ignition switch is OFF and the key

is removed from the switch.

WARNING

Beforejackingupthemachine,reviewandfollow

Jacking Instructions in Chapter 1 -- Safety.

Hydraulic System

Page 4 -- 64

Groundsmaster 5900/5910

Product Specification

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 5900, Toro Groundsmaster 5910 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |