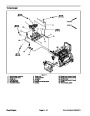

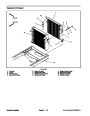

Removal (Fig. 8)

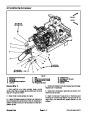

B. Position new manifold gasket and exhaust man-

ifold to cylinder head and secure with eight (8) flange

head screws. Tighten the screws in the sequence

shown in Figure 10. Torque screws 33 ft--lb (45

N--m).

CAUTION

The engine and exhaust system may be hot. To

avoid possible burns, allow the engine and ex-

haust system to cool before working on the ex-

haust system.

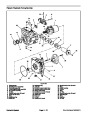

C. Secure turbocharger to exhaust manifold (see

Turbocharger Installation in this section).

3.

Install muffler and/or exhaust tube to the engine us-

ing Figure 8 as a guide. Torque exhaust clamp (item 1)

from 50 to 70 in--lb (5.7 to 7.9 N--m).

1.

Park machine on a level surface, lower cutting

decks, stop engine, engage parking brake and remove

key from the ignition switch.

4.

is approximately parallel to the ground. Loosen clamp

and adjust tailpipe if necessary.

After exhaust system assembly, check that tailpipe

2.

Raise and support hood to allow access to exhaust

system.

5.

6.

Install and secure side panel to right side of frame.

Lower and secure hood.

3.

Remove side panel from right side of frame to allow

easier access to exhaust system components.

4.

as necessary using Figure 8 as a guide.

Removemufflerand/orexhausttubefromtheengine

Antiseize

lubricant

1

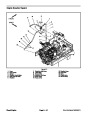

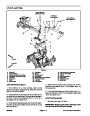

5.

(Fig. 9):

If necessary, remove exhaust manifold from engine

2

A. Remove turbocharger from exhaust manifold

(see Turbocharger Removal in this section).

4

B. Support exhaust manifold to prevent it from fal-

ling.

C. Remove eight (8) flange head screws thatsecure

exhaustmanifoldtocylinderhead.Removemanifold

from engine.

33

(45

ft--lb

N--m)

D. Remove and discard manifold gasket. Clean

mating surfaces of cylinder head and manifold.

3

6.

of time, cover openings to prevent any material from fal-

ling into openings.

If exhaust openings are to be left open for any length

Figure 9

1.

2.

Exhaust manifold

Manifold gasket

3.

4.

Engine

Flange screw (8 used)

Installation (Fig. 8)

NOTE: Make sure all exhaust system sealing surfaces

are free of debris or damage that may prevent a tight

seal.

1.

removal to prevent contamination entry.

Removeallcoversandplugsthatwereplacedduring

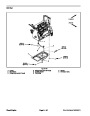

2.

Installexhaustmanifoldtoengineifremoved(Fig.9):

5

7

4

6

2

1

3

8

A. Apply antiseize lubricant to threads of flange

head screws used to secure exhaust manifold.

Figure 10

Groundsmaster 5900/5910

Page 3 -- 11

Diesel Engine

Product Specification

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 5900, Toro Groundsmaster 5910 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |