Traction Circuit: High Speed

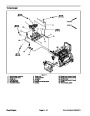

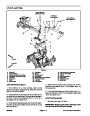

A variable displacement, bi--directional piston pump is

directly coupled to the engine flywheel to provide hy-

draulic flow for the traction circuit. The piston pump

swash plate movement is controlled by an electronic

proportional servo assembly.Pushing the traction pedal

rotates a potentiometer that sends a signal to the ma-

chine TEC--5002 controller. The controller in turn sends

a corresponding PWM (Pulse Width Modulation) output

signal to the hydrostat electronic control to rotate the

pumpswashplateaccordinglytocontrolthepump’sout-

put. The oilfromthehydrostat isdirected tothefrontand

rear wheel motors through the traction, 4WD and trac-

tion flush control manifolds.

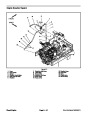

Forward Direction

With the Hi--Lo speed switch in the high range position,

solenoid valve (S) in the 4WD control manifold is ener-

gized. The solenoid valve spool shifts to direct charge

pressure that shifts the PD1 and PD2 control valve

spools. The shifted PD1 valve prevents hydraulic flow

from the hydrostat to the rear wheel motors. With flow

blocked to the rear wheel motors, all hydrostat flow is di-

rected to the front wheel motors to allow a higher, trans-

port speed in the forward direction.

Without flow to the rear wheel motors, the rotating rear

wheels drive the rear wheel motors so they act like a

pump. Inlet oil to the rear wheel motors is provided by a

check valve that allows charge oil into the rear wheel

motor circuit. Oil leaving the rear wheel motors enters

the4WDcontrolmanifoldatportM2andisdirectedback

to the rear wheel motors through the PD1 cartridge and

manifold port M1. To allow for rear wheel loop cooling

when in forward Transport operation, a small amount of

oil exits through the shifted PD2 cartridge and returns to

the charge circuit.

Operating pressure on the high pressure side of the

closed loop traction circuit is determined by the amount

of load developed at the fixed displacement wheel mo-

tors. As the load increases, circuit pressure can in-

crease to relief valve settings: 4330 PSI (299 bar) in the

forward direction and 5330 PSI (368 bar) in reverse. If

pressure exceeds the relief setting, oil flows through the

relief valve to the low pressure side of the closed loop

traction circuit.

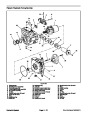

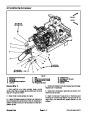

Reverse Direction

Traction circuit pressure (forward and reverse) can be

measured at test ports located on the hydrostat.

With the Hi--Lo speed switch in the high range position,

solenoid valve (S) in the 4WD control manifold is ener-

gized. The solenoid valve spool shifts to direct charge

pressure that shifts the PD1 and PD2 control valve

spools. Oil flow from the hydrostat port MA enters the

4WD control manifold at port P2, flows through the PR

pressure reducing valve and is stopped at the shifted

PD2 valve. With flow blocked to the rear wheel motors,

all hydrostat flow is directed to the front wheel motors to

allow a higher, transport speed in the reverse direction.

The traction circuit provides operation in either low

speed (four wheel assist) or high speed (two wheel

drive).

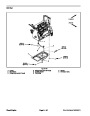

The traction pump and wheel motors use a small

amount of hydraulic fluid for internal lubrication. Fluid is

designed to leak across the pump and motor parts and

into the component case drain. This leakage results in

the loss of hydraulic fluid from the closed loop traction

circuit that must be replaced. The charge circuit is de-

signed to replace this traction circuit leakage.

Without flow to the rear wheel motors, the rotating rear

wheels drive the rear wheel motors so they act like a

pump. Inlet oil to the rear wheel motors is provided by a

check valve at the 4WD control manifold CH port that al-

lows charge oil into the rear wheel motor circuit. This

charge oil is routed through the shifted PD2 cartridge

and out manifold port M2 to the rear wheel motors. Re-

turn flow from the rear wheel motors enters the 4WD

control manifold atportM1,through theshifted PD1car-

tridge and and is then directed back to the rear wheel

motors as they turn in the reverse direction.

Thegearpumpsection(P3)thatsuppliesoiltothesteer-

ing, lift and cooling fan circuits, also provides charge oil

for the traction circuit. The gear pump is driven directly

off the traction pump. It provides a constant supply of

charge oil to the traction circuit to make up for oil that is

lost to internal leakage in the traction pump and wheel

motors. Charge pump flow is directed through the

charge oil filter before entering the hydrostat. This filter

has a bypass valve that allows charge oil flow to the

closed traction loop if the filter becomes plugged.

The charge pressure is limited to 330 PSI (22.8 bar) by

a relief valve located in the hydrostat. Charge pressure

can be measured atthe charge pressure test port on the

hydrostat.

Groundsmaster 5900/5910

Page 4 -- 15

Hydraulic System

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 5900, Toro Groundsmaster 5910 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)