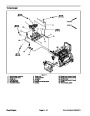

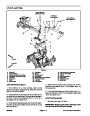

Removal (Fig. 13)

Park machine on a level surface, lower cutting

decks, stop engine, engage parking brake and remove

key from the ignition switch.

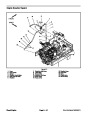

Installation (Fig. 13)

1.

1. Thoroughly clean the rear axle pivot shaft. Inspect

the shaft for wear or damage and replace if necessary.

2.

Position the rear axle assembly to the frame. Install

2.

3.

steering cylinders and rear wheel motors to prevent hy-

draulic system contamination.

Chock frontwheelstopreventmachine fromshifting.

Thoroughlycleanhydraulichoseendsandfittingson

thrust washer (item 19) between each side of axle and

frame. Raise axle assembly to frame and slide pivot

shaft through frame, thrust washers and axle. Make

sure that roll pin on pivot shaft is positioned in frame re-

liefs.

NOTE: To ease assembly, label hydraulic hoses to

show their correct position on the steering cylinders and

rear wheel motors.

3.

Install thrust washer (item 19) and lock nut (item 12)

onto pivot shaft. Tighten lock nut to eliminate any axial

movementofrearaxle.Makesurethataxlecanstillpivot

freely after lock nut is tightened.

4.

Disconnect the hydraulic hoses from the steering

cylinders and rear wheel motors. Put caps or plugs on

all fittings and hoses to prevent contamination.

4.

5.

Lower the machine to the ground.

Correctly install the hydraulic hoses to the steering

5.

Remove the lock nut (item 12) and thrust washer

(item19)thatsecurestheaxlepivotshaft(item13)tothe

frame.

cylinders and rear wheel motors.

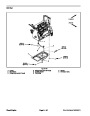

WARNING

CAUTION

Failure to maintain proper wheel lug nut torque

could result in failure or loss of wheel and may

result in personal injury.

When changing attachments, tires or perform-

ingotherservice,use correct blocks, hoistsand

jacks to raise and support machine. Make sure

machine is parked on a solid level surface such

as a concrete floor. Prior to raising machine, re-

move any attachments that may interfere with

the safe and proper raising of the machine. Al-

ways chock or block wheels. Use appropriate

jack stands to support the raised machine. If the

machine is not properly supported by jack

stands, the machine may move or fall, which

may result in personal injury.

6.

Make sure that wheel lug nuts are properly torqued

from 70 to 90 ft--lb (95 to 122 N--m).

7.

Check oil level in hydraulic reservoir.

8.

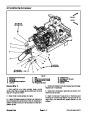

Lubricate the rear axle pivot bushings through the

grease fitting on the rear axle.

9.

at steering cylinders and wheel motors for leaks.

Operate machine and check hydraulic connections

10.After

assembly and adjustments have been com-

pleted, make sure that no contact is made between any

machine components as the rear wheels are moved

from steering lock to lock. Readjust if necessary.

6.

Jack up the machine (just ahead of the rear wheels)

until clearance exists to allow rear axle removal. Sup-

port the machine with appropriate jack stands prevent it

from falling.

7.

Support rear axle to prevent it from falling.

8.

Pull the axle pivot shaft from frame and rear axle.

This willrelease therearaxleandtwo(2) thrustwashers

(item 19) from the frame. Carefully lower the entire axle

assembly and remove it from under the machine.

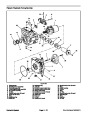

NOTE: If service to the rear wheel motors or steering

cylinders is required, refer to the Service and Repairs

section of Chapter 4 -- Hydraulic System.

Groundsmaster 5900/5910

Page 6 -- 19

Axles, Planetaries and Brakes

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 5900, Toro Groundsmaster 5910 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)