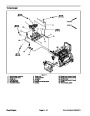

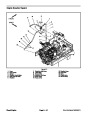

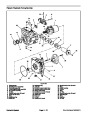

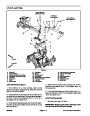

Disassembly (Fig. 99)

Removeoilfromsteering cylinderbyslowlypumping

thepistonrod.Afterremovingoilfromcylinder,plugboth

ports and thoroughly clean the outside of the cylinder.

4. Using a wrench on the piston rod flats to prevent the

rod from turning, install and tighten lock nut (item 16).

Torque lock nut to 40 ft--lb (54 N--m).

1.

5. Put a coating of clean hydraulic oil on all cylinder

parts to ease assembly.

2.

Remove snap ring (item 5) that secures head in bar-

rel.

6. Carefully slide piston rod assembly into cylinder bar-

rel taking care to not damage seals or O--rings.

3.

Grasp end of piston rod and use a twisting and pull-

ing motion to carefully extract piston, piston rod and

head from cylinder barrel.

7. Secure head in barrel with snap ring. Make sure that

snap ring is fully seated in groove in barrel.

4.

rodfromturning,removelock nut(item16)fromrod.Re-

move piston and head from rod.

Using a wrench on the piston rod flats to prevent the

8. If barrel end ball joint (item 20) was removed, install

ball joint to barrel as follows:

A. Thread ball joint into barrel so that roll pin hole in

joint aligns with hole in barrel.

5.

6.

pressed air. Do not wipe parts dry with paper towels or

cloth. Lint in a hydraulic system will cause damage.

Remove all seals and O--rings from head and piston.

Wash parts in clean solvent. Dry parts with com-

B. Drive roll pin into aligned holes in barrel and ball

joint.

C. Tighten jam nut.

7.

Carefully inspect internal surface of barrel for dam-

9.

If piston rod end ball joint (item 4) was removed, fully

age (deep scratches, out--of--round, etc.). Replace en-

tire cylinder if barrel is damaged. Inspect piston rod and

piston for evidence ofexcessive scoring, pitting or wear.

Replace any damaged parts.

retract piston rod and thread ball joint onto rod so that

center to center length is from 14.270” to 14.330” (362.5

to 363.9 mm) (Fig. 100). Tighten cap screw (item 2) and

lock nut (item 3).

8.

loosen cap screw (item 2) and lock nut (item 3) and then

unscrew ball joint from piston rod.

If piston rod ball joint (item 4) removal is necessary,

9.

If necessary, remove barrel end ball joint (item 20)

from barrel as follows:

A. Loosen jam nut (item 19).

B. Drive roll pin (item 18) from barrel.

C. Unscrew ball joint from barrel.

Assembly (Fig. 99)

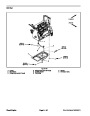

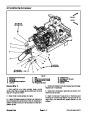

14.270”

to 14.330”

(362.5

to 363.9 mm)

Figure 100

1.

der. Put a coating of clean hydraulic oil on all new seals

and O--rings.

Use a complete repair kit when rebuilding the cylin-

2.

new O--ring, back--up ring, rod seal and rod wiper to

head.

Install new O--ringsand slipper seal tothe pistonand

3.

Lubricate shaft with clean hydraulic oil. Slide head

and piston onto piston rod.

Groundsmaster 5900/5910

Page 4 -- 137

Hydraulic System

Product Specification

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 5900, Toro Groundsmaster 5910 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |