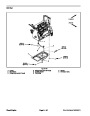

6.

Apply Permatex Blue Gel medium strength thread-

locker (or equivalent) to threads of cap screw (item 23).

Securepivothubtopivotshaftwithwasher(item24)and

cap screw. Torque cap screw from 77 to 96 ft--lb (105

to 130 N--m).

8

10

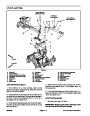

7.

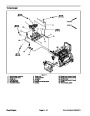

arm (Fig. 12):

Install joint yoke and cutting deck connection to lift

4

9

5

A. Make sure that spacer and thrust washer are

installed on joint yoke.

6

7

1

B. Raise joint yoke, cutting deck connection and

wing deck impact arm assembly to liftarm. Slidejoint

yoke into lift arm bore.

2

6

C. Place second thrust washer onto joint yoke shaft

and then place washer(s) (item 5 in Figure 12) as

needed to remove as much clearance as possible

between second thrust washer and hardened wash-

er (item 4) location.

3

D. Install slotted hex nut to secure joint yoke to lift

arm. Torque hex nut from 150 to 180 ft--lb (204 to

Figure 12

244

N--m).Makesurethatjointyokerotatesinliftarm

1.

2.

3.

4.

5.

Lift arm (LH shown)

Joint yoke

Deck connection

Hardened washer

Thrust washer

6.

7.

8.

9.

Thrust washer

Spacer

Rear impact arm

Slotted hex nut

without binding and that excessive clearance does

not exist in yoke assembly.

10. Cotter pin

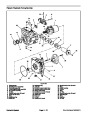

8.

hub (see Wing Deck Rear Impact Arm Assembly in this

section).

Secure wing deck rear impact arm assembly to pivot

3

7

9.

Position and install wing cutting deck to machine

1

(see Wing Cutting Unit in Chapter 8 -- Cutting Units).

10.Lubricate

complete.

lift arm grease fittings after assembly is

11.

tingdecktoverifythathydraulichosesandfittingsdonot

contact anything.

Afterassemblyiscompleted,raiseandlowerthecut-

6

5

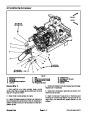

12.When

lift arm is fully raised, check that gap between

lift arm and bumper pad (item 32) is approximately

(2.5 mm). If necessary,add or remove shim pads

(item 31) so that gap is correct.

2

0.100”

4

3

1

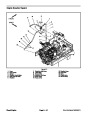

Figure 13

13.When

bracket should be contacted slightly by the lift arm (Fig.

lift arm is fully raised, the bumper on the stop

1.

2.

3.

4.

Bumper

5.

6.

7.

LH stop bracket

Flange nut

RH stop bracket

Flange head screw

Bumper shim

Lock nut

13).

There should be less than one (1) bumper shim of

interference. Ifnecessary,addorremove bumpershims

so that slight contact exists.

14.Verify

switch.

correct operation of wing deck proximity

Chassis

Page 7 -- 14

Groundsmaster 5900/5910

Product Specification

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 5900, Toro Groundsmaster 5910 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |