4.

With ignition switch in the ON position (engine not

7. Shut engine off.

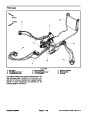

After adjustments have been made and all fasteners

are tightened, make sure that traction rod does not con-

tact anything through both forward and reverse direc-

tions.

running), use Diagnostic Display to make sure that neu-

tral switch is closed when traction pedal is released to

theneutraldetentposition(seeDiagnosticDisplayinthe

Troubleshooting section of Chapter 5 -- Electrical Sys-

tem).

8.

9.

Lower machine to ground.

Adjustments with Engine Running

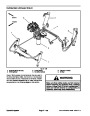

CAUTION

1

5

Allwheelswillbeoffthegroundandrotatingdur-

ing the following procedure. Make sure machine

is supported so it will not move and accidentally

fall to prevent injuring anyone near the machine.

3

1.

ground (see Jacking Instructions in Chapter 1 -- Safety).

Raise and support machine so all wheels are off the

4

2.

Start engine and make sure that Hi/Low switch is in

the Low (4WD) position. Depress traction pedal to allow

oilflowthroughthetraction circuit.Allowallwheels toro-

tate to warm up the hydraulic oil.

2

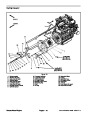

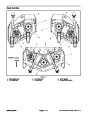

Figure 56

3.

The traction pedal should contact the pedal stop

when fully depressed. At this point, the piston pump

should be at full stroke.

1.

2.

3.

Pedal stop height

Traction pump end

Rod end dimension

4.

5.

Traction lever end

Neutral adjustment

4.

When traction pedal is released from either forward

or reverse, pedal should return to the neutral position

and wheels should stop rotating. If necessary, adjust

spring shaft (item 5 in Fig. 56) until neutral operation is

correct.

1

3

5.

With the engine running, the transport cylinder on

engine should extend when Hi/Low speed switch is

moved to the Hi speed (2WD) position. This cylinder ex-

tension prevents the piston (traction) pump swash plate

from reaching full stroke when in Hi speed (2WD). Also,

the traction pedal should not contact the pedal stop

when fully depressed in Hi speed (2WD).

2

4

6.

Adjust the transport cylinder as follows (Fig. 57):

A. PlaceHi/LowspeedswitchintheHispeed(2WD)

position.

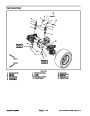

Figure 57

B. Lock one front wheel by applying the wheel

brake.

1.

2.

Transport cylinder

Pump control arm

3.

4.

Cap screw

Jam nut

C. Use a phototac to measure the other front wheel

speed. When the traction pedal is fully depressed to

forward, the wheel speed should be from 370 to 422

RPM.

D. If wheel speed is incorrect, adjust cap screw in

transport cylinder to provide correct wheel speed.

Make sure that jam nut is tightened after any adjust-

ment.

Groundsmaster 4000--D/4010--D

Page 4 -- 71

Hydraulic System

Product Specification

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 10176SL, Toro Groundsmaster 30446, Toro Groundsmaster 30448, Toro Groundsmaster 4010 D |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |