8.

corner of 4WD hydraulic manifold to rear axle mount

bracket.

Remove cap screw and flange nut that secures front

1

2

3

4

9.

If required, remove tie rod ends from steering arms

on rear axle (Fig. 13). Remove the cotter pins and castle

nuts from the tie rod ball joints. Use a ball joint fork and

remove the tie rod ends from the axle steering arms.

10.Support

rear axle to prevent it from falling. Remove

six (6) cap screws, flat washers and flange nuts that se-

cure rear axle mount to equipment frame. Lower rear

axle and rear axle mount from machine.

5

11.

Remove lock nut and washer from pivot pin that at-

taches rear axle to rear axle mount. Remove washer

headscrewthatsecuresflangeofpivotpintoaxlemount

(Fig. 14).

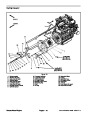

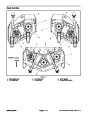

Figure 12

1.

2.

3.

Hydraulic hose

Hydraulic hose

Hydraulic tube

4.

5.

Hydraulic tube

Axle mount bracket

12.Remove

pivot pin. Separate rear axle mount from

rear axle. Note location of thrust washers on both ends

of axle mounting boss.

4

5

3

2

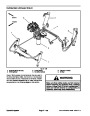

Installation (Fig. 11)

1.

Position rear axle mount to axle. Install thrust wash-

1

ers between axle boss and axle mount. The thinner

thrust washer should be installed on the hydraulic motor

end of the axle (toward the rear of the machine). With

washers installed, there should be from 0.002” to 0.020”

(0.05

mm to 0.51 mm) clearance between rear axle

6

mount and axle mounting boss. Add thrust washers if

needed to adjust clearance.

2.

Install axle pivot pin to secure axle to rear axle

mount. Install washer and lock nut onto pivot pin. Tight-

en lock nut and then loosen it slightly to allow the axle

pin to pivot freely. Secure pivot pin to axle mount with

washer head screw (Fig. 14).

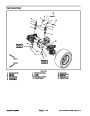

Figure 13

1.

2.

3.

Tie rod

Dust cover

Cotter pin

4.

5.

6.

Castle nut

Tie rod end

Steering arm (LH)

3.

jack, raise assembly to machine frame and align mount-

ing holes of rear axle mount and machine frame.

Position axle and rear axle under machine. With a

4.

screws, flat washers and flange nuts.

Secure rear axle mount to frame with six (6) cap

2

1

5.

corner of 4WD hydraulic manifold to rear axle mount

bracket.

Install cap screw and flange nut that secures front

6.

Tighten ball joint castle nuts and install new cotter pins.

If removed, install the tie rod to rear axle (Fig. 13).

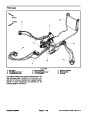

Figure 14

7.

Attach steering cylinder hydraulic tubes to rear axle

1.

Pivot pin

2.

Washer head screw

mount bracket with washers and bulkhead lock nuts

(Fig. 12). Install steering cylinder hoses to hydraulic

tubes.

Groundsmaster 4000--D/4010--D

Page 6 -- 17

Axles, Planetaries and Brakes

Product Specification

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 10176SL, Toro Groundsmaster 30446, Toro Groundsmaster 30448, Toro Groundsmaster 4010 D |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |