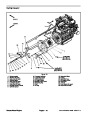

Engine Cooling Fan Circuit

A four section gear pump is coupled to the piston (trac-

tion)pump.Thegearpumpsection farthestfromthepis-

ton pump supplies hydraulic flow for the engine cooling

fan circuit (Fig. 15).

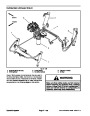

ing oil flow to return to the fan motor but in the reverse

direction causing the motor and cooling fan to run in re-

verse. The controller determines the length of time that

the fan should be run in reverse before fan rotation is re-

turned to the forward direction.

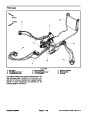

The fan drive manifold controls the operation of the hy-

draulic motor that drives the engine cooling fan in addi-

tion to including the flow divider for the steering and

lift/lower circuits. The fan drive manifold controls the

speed and direction of the fan motor based on electrical

output from the TEC--5002 controller.

2

Oil flow from the gear pump to the cooling fan motor is

controlled by the proportional relief valve (PRV) in the

fan drive manifold. This valve adjusts fan circuit pres-

sure and flow based on a PWM (Pulse Width Modula-

tion)signalfromtheTEC--5002controller.Thecontroller

uses engine coolant and hydraulic oil temperatures as

inputstodeterminetheproperPWMsignalforthe(PRV)

valve. The fan circuit flow determines the speed of the

cooling fan motor and thus, the speed of the cooling fan.

1

If the fan motor is stalled for any reason, the manifold

proportional reliefvalve(PRV)hasasecondary function

as a circuit relief to limit fan motor pressure to 3000 PSI

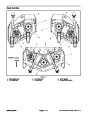

Figure 15

(207

bar).

1.

Gear pump

2. Fan drive manifold

When the engine is shut off, the over--running inertia

load of the fan blades keeps driving the fan motor and

turnsitintoapump.Thecheckvalve(CV)inthefandrive

manifold will open to keep the motor circuit full of oil so

the fan motor will not cavitate.

REVERSE DIRECTION SHOWN

TO RESERVOIR

TO STEERING

CIRCUIT

TO LIFT/LOWER

CIRCUIT

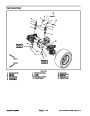

Forward Direction Fan Operation

M1

M2

L

Oilflowfromthegearpumpissentthrough thede--ener-

gizedfanmanifoldsolenoidvalve(S1)torotatethecool-

ing fan motor. Return flow from the motor re--enters the

manifold (port M2), through the de--energized solenoid

valve(S1), outofthemanifold (portT) andthen isrouted

through the oil cooler and oil filter.

(ENERGIZED)

Reverse Direction Fan Operation (Fig. 16)

The TEC--5002 controller can reverse the cooling fan to

clean debris from the rear intake screen. If hydraulic oil

and/or engine coolant temperatures increase to an un-

suitable level, a high PWM signal is sent to the (PRV)

valve to slow the cooling fan and direct pump oil flow to

the reservoir. The controller then energizes solenoid

valve(S1)inthefandrivemanifoldtoreversecoolingfan

motor oil flow so that the motor runs in the reverse direc-

tion. A lower PWM signal is sent to the PRV valve allow-

P1

T

P2

FAN DRIVE

MANIFOLD

FROM GEAR PUMP

TO OIL COOLER

Figure 16

Groundsmaster 4000--D/4010--D

Page 4 -- 25

Hydraulic System

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 10176SL, Toro Groundsmaster 30446, Toro Groundsmaster 30448, Toro Groundsmaster 4010 D |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)