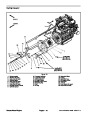

NOTE: Theplanetarywheeldriveassemblycanbeser-

vicedwiththeplanetaryinstalledtomachine(seePlane-

tary Wheel Drive Service in this section). Use the

following procedure to remove and install planetary

wheel drive assembly from machine.

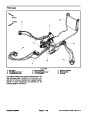

2. Install brake assembly (see Brake Assembly Instal-

lation in this section).

3.

Install hydraulic wheel motor (see Front Wheel Mo-

tors in the Service and Repairs section of Chapter 4 --

Hydraulic System).

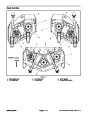

Removal (Fig. 7)

4.

Install wheel assembly.

1.

decks, stop engine and remove key from the ignition

switch.

Park machine on a level surface, lower cutting

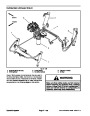

WARNING

2.

Drainoilfromplanetary wheeldrive/brake assembly.

Failure to maintain proper wheel lug nut torque

could result in failure or loss of wheel and may

result in personal injury.

CAUTION

5.

from 85 to 100 ft--lb (115 to 135 N--m).

Lower machine from jack stands. Torque lug nuts

When removing front wheel, use correct jacks

and supports. Make sure machine isparked on a

solid, level surface such as a concrete floor.

Prior to raising machine, remove any attach-

ments that may interfere with the safe and prop-

erraisingof themachine. Alwayschock orblock

wheels. Use jack stands to support the raised

machine. If the machine is not properly sup-

ported by jack stands, the machine may move or

fall, which may result in personal injury.

6.

Make sure drain plug is installed in bottom of brake

assembly (Fig. 8). Fill planetary wheel drive/brake as-

sembly with SAE 85W--140 gear lube. Capacity is

approximately 16 fl. oz. (0.47 liters) per wheel.

7.

eration.

Check and adjust brake cables for proper brake op-

1

3.

Chock rear wheels and jack up front of machine (see

JackingInstructions inChapter1 -- Safety).Supportma-

chine with jack stands.

4.

5.

Remove front wheel assembly.

2

Remove hydraulic wheel motor (see Front Wheel

Motors in the Service and Repairs section of Chapter 4

--

Hydraulic System).

6.

Remove brake assembly (see Brake Assembly Re-

moval in this section).

3

7.

Supportplanetaryassemblytopreventitfromfalling.

Loosen and remove flange head screws that secure

planetary assembly to frame. Remove planetary as-

sembly from machine.

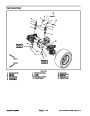

Figure 8

1.

2.

Brake housing

Check plug

3.

Drain plug

Installation (Fig. 7)

1.

flange head screws that secure planetary assembly.

Position planetary assembly to machine. Install

Torque screws in a crossing pattern from 75 to 85 ft--lb

(101

to 115 N--m).

Groundsmaster 4000--D/4010--D

Page 6 -- 11

Axles, Planetaries and Brakes

Product Specification

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 10176SL, Toro Groundsmaster 30446, Toro Groundsmaster 30448, Toro Groundsmaster 4010 D |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |