Cutting Deck Motor

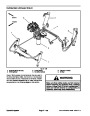

Removal

5. Securemotortocuttingdeckwithtwo(2)flangehead

screws (Fig. 99).

1.

Park machine on a level surface, lower cutting

decks, stop engine, apply parking brake and remove

key from the ignition switch.

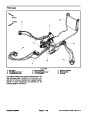

6. Remove caps or plugs from fittings and hoses. Con-

nect hydraulic hoses to deck motor (see Hydraulic Hose

and Tube Installation in the General Information section

of this chapter).

2.

Installing Hydraulic System Components at the begin-

ning of the Service and Repairs section of this chapter.

Read the General Precautions for Removing and

7. After assembly is completed, verify that hydraulic

hoses and fittings are not contacted by moving compo-

nents.

3.

Thoroughly clean exterior of deck motor and fittings.

Disconnecthydrauliclinesfrommotor.Putcapsorplugs

on fittings and hoses to prevent contamination. Tag hy-

draulic lines for proper installation.

4.

draulic motor to motor mount (Fig. 99).

Remove two (2) flange head screws that secure hy-

1

5.

Carefully remove hydraulic motor from cutting deck

taking care not to damage spider hub attached to motor.

Locate and remove spider and mounting shim(s) (if

equipped) from the deck.

2

2

6.

If necessary, straighten tab washer and remove nut,

tab washer and spider hub from motor shaft.

7.

If hydraulic fittings are to be removed from motor,

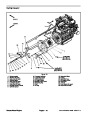

Figure 99

mark fitting orientation to allow correct assembly. Re-

move fittings from motor and discard O--rings.

1.

Deck motor (RH shown)

2. Flange head screw

7

8

5

2

Installation

6

1.

If fittings were removed from motor, lubricate and

4

9

3

place new O--rings onto fittings. Install fittings into port

openingsusingmarksmadeduringtheremovalprocess

to properly orientate fittings. Tighten fittings (see Hy-

draulic Fitting Installation in the General Information

section of this chapter).

4

2

27

(37

to 33 ft--lb

to 44 N--m)

10

1

15

11

14

13

2.

If removed, install spider hub on motor shaft. Secure

with tab washer and nut. Torque nut from 27 to 33 ft--lb

to 44 N--m). Bend small tab of washer into keyway

and large tab against nut.

12

(37

3.

Check for proper clearance between spider hub and

spindle pulley. Install motor to cutting deck without plac-

ing the spider in the spindle pulley. The clearance be-

tween hub and pulley valleys should be from 0.830” to

0.930”

(21.1 to 23.6 mm). If required, use mounting

shim(s) between motor and motor mount to adjust clea-

rance.

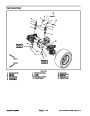

Figure 100

1.

2.

3.

4.

5.

6.

7.

8.

Cutting deck motor

O--ring

Hydraulic adapter

O--ring

Flange head screw

O--ring

Hydraulic adapter

O--ring

9.

90o hydraulic fitting

4.

Position spider in spindle pulley. Place mounting

10. Woodruff key

11. Shim (if required)

12. Spider

shim(s) (if required) on deck. Carefully install hydraulic

motor to the cutting deck taking care not to damage spi-

der hub attached to motor.

13. Nut

14. Tab washer

15. Spider hub

Groundsmaster 4000--D/4010--D

Page 4 -- 129

Hydraulic System

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 10176SL, Toro Groundsmaster 30446, Toro Groundsmaster 30448, Toro Groundsmaster 4010 D |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)