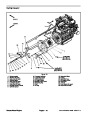

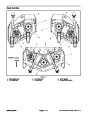

Removal (Fig. 1)

Park machine on a level surface, lower cutting

decks, stop engine and remove key from the ignition

switch.

25

24

1.

6

23

21

22

2.

Drainoilfromplanetary wheeldrive/brake assembly.

5

1

2

CAUTION

3

9

20

6

4

7

When removing front wheel, use correct jacks

and supports. Make sure machine isparked on a

solid, level surface such as a concrete floor.

Prior to raising machine, remove any attach-

ments that may interfere with the safe and prop-

erraisingof themachine. Alwayschock orblock

wheels. Use jack stands to support the raised

machine. If the machine is not properly sup-

ported by jack stands, the machine may move or

fall, which may result in personal injury.

19

21

18

22

17

8

11 10

16

9

12

13

14

15

3.

Chock rear wheels and jack up front of machine (see

JackingInstructions inChapter1 -- Safety).Supportma-

chine with jack stands.

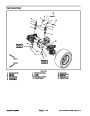

Figure 2

1.

2.

3.

4.

5.

6.

7.

8.

9.

Brake lever

14. Compression spring

15. Brake link

16. Brake assembly

17. Jam nut

18. Spring plate

19. Jam nut

20. Brake cable

21. Flat washer

22. Cotter pin

4.

5.

Remove front wheel assembly.

Thrust washer (2 used)

Flat washer

Lock nut

Remove hydraulic wheel motor (see Front Wheel

Bushing

Motors in the Service and Repairs section of Chapter 4

Clevis pin

Lock nut

--

Hydraulic System).

Cap screw

Brake link

6.

frame bracket and pull rod on brake assembly (Fig. 2).

Disconnect brake link assembly from brake lever,

10. Rod end (LH thread)

23. Screw (2 used)

24. Cable bracket

25. Frame rail

11.

12.

13.

Jam nut (LH thread)

Hex link

Flanged spacer

7.

Support brake assembly to prevent it from falling.

8.

Remove flange head screws (item 9) securing brake

assembly to frame.

Remove brake assembly from machine. Be careful

3

9.

to not drop splined brake shaft (item 3) as brake assem-

bly is removed.

10.Remove

splined brake shaft from brake assembly.

11.

that all gasket material is removed from both brake and

planetary assemblies.

Remove and discard gasket (item 18). Make sure

2

1

12.Complete

brake inspection and repair (see Brake In-

spection and Repair in this section).

Installation (Fig. 1)

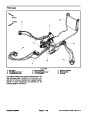

Figure 3

1.

2.

Brake housing

Check plug

3.

Brake link assembly

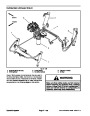

1.

Install splined brake shaft (item 3) into brake assem-

bly. NOTE: The stepped end of the splined brake shaft

must be aligned toward the hydraulic wheel motor (Fig.

4).

Groundsmaster 4000--D/4010--D

Page 6 -- 5

Axles, Planetaries and Brakes

Product Specification

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 10176SL, Toro Groundsmaster 30446, Toro Groundsmaster 30448, Toro Groundsmaster 4010 D |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |