5.

switch on piston pump.

Disconnect wire harness connector from neutral

6. Connect wire harness connector toneutral switch on

traction pump.

6.

Installing Hydraulic System Components at the begin-

ning of the Service and Repairs section of this chapter.

Read the General Precautions for Removing and

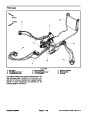

7. Remove plugs or caps from disconnected hydraulic

hoses and open ports of the pump assembly. Install fit-

tings and hoses to correct location on gear and piston

pumps (see Hydraulic Fitting Installation and Hydraulic

Hose and Tube Installation in the General Information

section of this chapter).

7.

connect to gear pump and piston pump.

Forinstallationpurposes,labelallhydrauliclinesthat

8.

Put a drain pan below the pump assembly. Remove

8.

Lower machine to ground.

hydraulic hoses and fittings connected to piston and

gear pumps. Putplugs orcaps on disconnected hydrau-

lic hoses to prevent contamination of the system. Put

plugs in open ports of pumps.

9. Install new filter and fill hydraulic reservoir with cor-

rect oil.

IMPORTANT: Refer to Traction Circuit Component

Failure in the General Information section of this

chapter for information regarding the importance of

removing contamination from the traction circuit.

NOTE: If fuel tank is removed from the machine, the

gear pump and piston pump can be removed as a com-

plete assembly.

9.

Removal in this section).

Remove gear pump from machine (see Gear Pump

10.Disconnect engine run solenoid electrical connector

to prevent engine from starting. Prime pumps by turning

ignition key switch to crank engine for ten (10) seconds.

Let starter cool and then repeat cranking procedure

again.

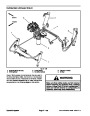

10.Support

the piston pump to prevent it from falling

while removing two (2) cap screws and washers retain-

ing pump assembly to engine flywheel plate. Carefully

pull pump assembly from flywheel plate and raise it out

of the machine.

11.Connect engine run solenoid electrical connector,

start the engine and check for proper operation.

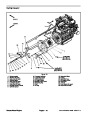

Installation (Fig. 68)

12.Properly fill hydraulic system (see Charge Hydraulic

System in this section).

IMPORTANT: To prevent spring coupler damage,

make sure that piston pump is properly supported

anddoesnotputsideloadintocouplerduringpump

installation.

13.Stop engine and check for hydraulic oil leaks. Check

hydraulic reservoir oil level.

1.

Carefully raise piston pump into the machine, align

5

8

3

1

pump input shaft to spring coupler on engine and posi-

tion it to the engine flywheel plate. Support pump to pre-

vent it from producing any side load into coupler and

also to align pilot diameter of pump to flywheel plate

bore.

2

6

2.

screws (item 6) used to secure piston pump to engine

flywheel plate.

Apply Loctite #242 (or equivalent) to threads of cap

4

3.

While maintaining pump alignment with spring cou-

7

pler and flywheel plate, install two (2) cap screws and

washers to secure piston pump to engine. Torque

screws from 79 to 84 ft--lb (108 to 113 N--m).

Figure 69

4.

Install gear pump to piston pump (see Gear Pump

Installation).

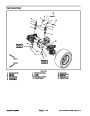

1.

2.

3.

4.

Piston pump

Cap screw

Pump control arm

Spacer

5.

6.

7.

8.

Lock nut

Jam nut

Traction rod

Rod end

5.

Position traction rod to control arm on piston pump

by installing cap screw, spacer and lock nut (Fig. 69).

Groundsmaster 4000--D/4010--D

Page 4 -- 87

Hydraulic System

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 10176SL, Toro Groundsmaster 30446, Toro Groundsmaster 30448, Toro Groundsmaster 4010 D |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)