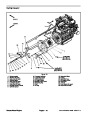

Transport Cylinder

A transport cylinder is included in the traction circuit to

reduce traction pump control arm movement when op-

erating in Hi speed (2WD). This reduced control arm

movement limits pump swash plate rotation to prevent

excessive transport speed. The transport cylinder is at-

tached to the forward, right side engine mount (Fig. 66).

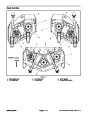

13

3

14

1

RIGHT

FRONT

12

11

Disassembly (Fig. 66)

10

1.

decks, stop engine, apply parking brake and remove

key from the ignition switch. Raise and support hood.

Park machine on a level surface, lower cutting

2

4

5

6

2.

removal, thoroughly clean exterior of pump assembly.

To prevent contamination of hydraulic system during

7

8

9

1

6 15

3.

Installing Hydraulic System Components at the begin-

ning of the Service and Repairs section of this chapter.

Read the General Precautions for Removing and

Figure 66

1.

2.

3.

4.

5.

6.

7.

8.

Carriage screw (2 used)

Cylinder spacer

Transport cylinder

Lock nut (2 used)

Piston

9. Seal

10. O--ring

11. Fitting

12. O--ring

13. Hydraulic hose

14. RH engine mount

15. Jam nut

4.

hydraulic hose from cylinder fitting. Put plugs in hose

and fitting to prevent contamination of the system.

Putadrainpanbelowthetransportcylinder.Remove

Backup ring (2 used)

O--ring (2 used)

Retaining ring

16. Cap screw

5.

mount. Locate and remove cylinder spacer from be-

tween transport cylinder and engine mount.

Remove transport cylinder assembly from engine

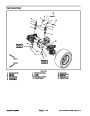

1

6.

If cap screw is to be removed from piston, carefully

2

measure the distance from the piston to the end of the

cap screw before loosening the jam nut (Fig. 67). This

distance will be necessary for assembly.

7.

guide.

Disassemble transport cylinder using Figure 66 as a

3

Assembly (Fig. 66)

MEASURE

DISTANCE

1.

Lubricate all transport cylinder components with

clean hydraulic oil. Assemble transport cylinder and

install cylinder to engine mount using Figure 66 as a

guide. Make sure that cylinder spacer is between trans-

port cylinder and engine mount.

Figure 67

1.

2.

Transport cylinder

Cap screw

3.

Pump control arm

2.

If the cap screw was removed from the piston, make

sure that distance from the piston to the end of the cap

screw is the same as the distance measured before dis-

assembly (Fig. 67).

3.

Remove plugs from hose and fitting. Install hose to

fitting on transport cylinder (see Hydraulic Hose and

Tube Installation in the General Information section of

this chapter).

Groundsmaster 4000--D/4010--D

Page 4 -- 85

Hydraulic System

Product Specification

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 10176SL, Toro Groundsmaster 30446, Toro Groundsmaster 30448, Toro Groundsmaster 4010 D |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |