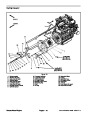

Joint Yoke Disassembly

Remove retaining rings from yoke and deck mount.

5. Install retaining rings to yoke and deck mount to se-

cure bearings in place.

1.

6.

Make sure that assembled joint yoke moves without

IMPORTANT: Support yoke when removing cross

and bearings to prevent yoke damage.

binding. Slight binding can usually be eliminated by

lightly rapping the yoke lugs with a soft faced hammer.

If binding continues, disassemble joint yoke and deck

mount to identify and eliminate source of binding.

2.

Use a press to remove yoke from deck mount:

A. Place a small socket against one bearing in the

deck mount and a large socket on the opposite side

of the mount.

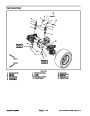

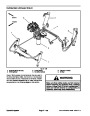

Installation (Fig. 11)

1.

2.

Position joint yoke with deck mount to cutting deck.

Securedeckmounttodeckwitheight(8)capscrews,

B. While supporting the large socket, apply pres-

sure on small socket to partially push the opposite

bearing into the large socket.

lock washers and flat washers (Fig. 12).

3.

Place spacer washer (chamfered ID side down) and

C. Remove assembly from press, grasp partially re-

moved bearing and tap on yoke to completely re-

move the bearing.

then thrust washer (item 11) onto joint yoke shaft. Insert

yoke shaft up through liftarmbushings. Placeadditional

thrust washers (items 11 and 21) and then hardened

washer (item 12) on yoke shaft and secure with slotted

hex nut. Torque nut from 150 to 180 ft--lb (203 to 244

N--m) while aligning hole in shaft with slot in nut. Install

cotter pin.

D. Repeat process for remaining bearing.

E. Remove yoke from mount.

3.

Use a press and the above process to remove bear-

4.

assembly. Secure rod end of rear arm assembly to deck

mount with cap screw and lock nut.

Position spacers on both sides ofrod end of rear arm

ings and cross from yoke.

Thoroughly clean and inspect all components.

Joint Yoke Assembly

4.

5.

tion on machine.

Grease joint yoke and lift arm bushings after installa-

1.

5)

Make sure that rubber plate (item 6) and plate (item

are positioned in bottom of deck mount.

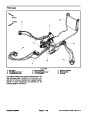

6.

tingdecktoverifythathydraulichosesandfittingsdonot

contact anything.

Afterassemblyiscompleted,raiseandlowerthecut-

2.

Apply a coating of grease to bearing bores of yoke

and deck mount. Also, apply grease to bearings and

sealofbearingassembly.Makesurethatallbearingroll-

ers are properly seated in bearing cage.

2

3

1

3.

Use a press to install cross and bearings into yoke.

A. Press one bearing partially into yoke.

IMPORTANT: Take care when installing cross

into bearing to avoid damaging bearing seal.

B. Carefully insert cross into bearing and yoke.

5

4

C. Hold cross in alignment and press bearing inuntil

it hits the yoke.

D. Carefully place second bearing into yoke bore

and onto cross shaft. Press bearing into yoke.

Figure 12

1.

2.

3.

Lift arm (RH shown)

Joint yoke

Rear arm assembly

4.

5.

Deck mount

Cap screw/washers

4.

mount to yoke.

Use a press and the above process to install deck

Groundsmaster 4000--D/4010--D

Page 7 -- 13

Chassis

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 10176SL, Toro Groundsmaster 30446, Toro Groundsmaster 30448, Toro Groundsmaster 4010 D |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)