6.

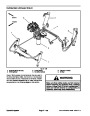

caps or plugs on open hydraulic lines and fittings. Label

disconnected hydraulic lines for proper installation.

Disconnect hydraulic lines from manifold and put

2

3

1

7.

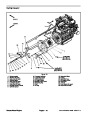

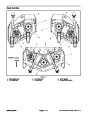

Remove lift/lower manifold using Figure 109 as a

guide.

4

IMPORTANT: The fitting in manifold port C2 in-

cludes a .070 orifice to control the lowering speed

of the front deck. If this fitting is removed from the

manifold, label its position for assembly purposes.

8.

If hydraulic fittings are to be removed from control

manifold,markfittingorientation toallowcorrectassem-

bly. Remove fittings from valve and discard O--rings

(Fig. 111).

IMPORTANT: A flow control orifice is placed be-

neath the hydraulic fittings in lift/lower manifold

ports C2, C4 and C6. If any of these fittings is re-

moved from the manifold, make sure to remove ori-

fice and label its position for assembly purposes.

Also note location of groove in orifice for assembly

purposes. When installing the orifice in the man-

ifold, make sure that the orifice is flat in the base of

the port. Manifold damage is possible if the orifice

is cocked in the port.

Figure 110

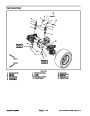

1.

2.

Controller cover

Screw (2 used)

3.

4.

Flat washer (2 used)

U--nut (2 used)

FRONT

25

ft--lb

(34

N--m)

Installation (Fig. 109)

2

3

1.

If fittings were removed from control manifold, lubri-

1

cate and place new O--rings onto fittings. Correctly

place orifice in port C2, C4 or C6 if removed. Install fit-

tingsintoportopeningsusingmarksmadeduringthere-

moval process to properly orientate fittings (Fig. 111).

Tighten fittings (see Hydraulic Fitting Installation in the

General Information section of this chapter).

6

7 8

13 9

10

2.

Installlift/lowermanifoldusingFigure109asaguide.

9

3.

Remove caps and plugs from fittings and hydraulic

3

4

lines. Using labels placed during manifold removal,

properly connect hydraulic lines to manifold (see Hy-

draulic Hose and Tube Installation in the General Infor-

mation section of this chapter).

6

2

34 N--m)

5 ft--lb

5

(

12

11

Figure 111

1.

2.

3.

4.

5.

6.

7.

O--ring

8.

9.

O--ring

O--ring

4.

connect wire harness connectors to the solenoid valve

coils on the lift/lower manifold.

Usingtagsplacedduringmanifoldremoval,correctly

Dust cap

Test port

10. 45 hydraulic fitting

o

Orifice (.063)

Straight fitting

O--ring

11. 45o hydraulic fitting

12. O--ring

13. Fitting with orifice (.070)

5.

right side of the operator seat (Fig. 110).

Install support bracket and controller cover to the

Orifice (.035)

6.

essary before returning machine to service.

Makesurehydraulic tankisfull.Addcorrectoilifnec-

7.

Lower and secure operator seat.

Groundsmaster 4000--D/4010--D

Page 4 -- 141

Hydraulic System

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 10176SL, Toro Groundsmaster 30446, Toro Groundsmaster 30448, Toro Groundsmaster 4010 D |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)