Procedure for Lift/Lower Circuit Relief Pressure

Test

B. To decrease pressure setting, remove cap on re-

liefvalve andturntheadjustment socketonthevalve

in a counterclockwise direction. A 1/8 turn on the

socket will make a measurable change in pressure

setting.

NOTE: Before attempting to check or adjust lift/lower

circuit relief pressure, make sure that counterbalance

pressure is correctly adjusted (see Counterbalance

Pressure Test in this section).

C. After relief valve adjustment, recheck pressure

setting and readjust as needed.

1.

Make sure hydraulic oil is at normal operating tem-

perature by operating the machine under load for

approximately ten (10) minutes. Make sure the hydrau-

lic tank is full.

9. Ifreliefvalveadjustmentdoesnotchangereliefpres-

sure, check for restriction in pump intake line, lift cylin-

der(s) internal leakage or gear pump damage.

2.

decks lowered and off. Make sure engine is off and the

parking brake is applied.

Park machine on a level surface with the cutting

10.When testing is completed, disconnect pressure

gauge from test port. Install controller cover.

2

3.

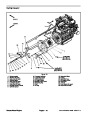

manifold (Fig. 47).

Remove controller cover to gain access to lift/lower

1

3

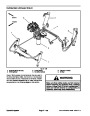

CAUTION

4

Prevent personal injury and/or damage to equip-

ment. Read all WARNINGS, CAUTIONS and Pre-

cautions for Hydraulic Testing at the beginning

of this section.

4.

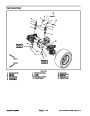

test port G1 on lift/lower manifold (Fig. 48).

Connect a 5,000 PSI (345 bar) pressure gauge to

5.

high idle speed (2870 RPM).

Sit on the seat and start the engine. Move throttle to

RIGHT

FRONT

6.

While sitting on the seat, depress the rear of one of

the lift switches to fully raise the cutting deck. Momen-

tarilyholdtheswitchwiththedeckfullyraisedwhilelook-

ing at the gauge.

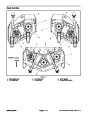

Figure 47

1.

2.

Controller cover

Screw (2 used)

3.

4.

Flat washer (2 used)

U--nut (2 used)

GAUGE READING TO BE approximately 1600 PSI

(110

bar).

7.

Release the lift switch, stop the engine and record

test results.

1

8.

lower manifold (Fig. 48). Adjustment of this valve can be

performed as follows:

Reliefvalve (RV1)islocated onthetopsideofthelift/

NOTE: Do not remove the relief valve from the hydrau-

2

lic manifold for adjustment.

3

A. To increase pressure setting, remove cap on re-

liefvalve andturntheadjustment socketonthevalve

in a clockwise direction. A 1/8 turn on the socket will

make a measurable change in pressure setting.

Figure 48

1.

2.

Lift/lower manifold

Test port G1

3.

Relief valve RV1

Groundsmaster 4000--D/4010--D

Page 4 -- 59

Hydraulic System

Product Specification

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 10176SL, Toro Groundsmaster 30446, Toro Groundsmaster 30448, Toro Groundsmaster 4010 D |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |