Raise Cutting Deck

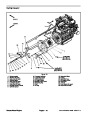

A four section gear pump is coupled to the piston (trac-

tion) pump. The third gear pump section supplies hy-

draulic flow to both the steering and lift/lower circuits.

Hydraulic flow from this pump section is delivered to the

two circuits through a proportional flow divider that is lo-

cated in the fan drive manifold. This flow divider splits

pump flow approximately 50% for the steering circuit

and 50% for the lift/lower circuit.

Raise Right Cutting Deck

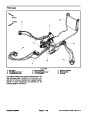

To raise the right deck, the rear of the right console

switch is depressed as an input to the TEC--5001 con-

troller. The controller provides an electrical output to so-

lenoid valves S1 and S7 in the lift/lower manifold. The

energized solenoid valves shift to allow a passage for

circuit oil flow to the barrel end of the right deck lift cylin-

der. Shifted S1 prevents oil flow from bypassing the lift

cylinders. Shifted S7 allows an oil path through the ori-

fice in manifold port C6 and to the barrel end of the right

lift cylinder to extend the lift cylinder and raise the right

cutting deck. Oil from the extending cylinder is directed

through S8 (de--energized), out manifold port CH, to the

oil filter and then to the traction charge circuit.

A relief valve (RV1) located in the lift/lower manifold lim-

its lift/lower circuit pressure to 1600 PSI (110 bar). An

adjustable valve (RV2) in the lift/lower manifold main-

tains back pressure (counterbalance) on the deck lift

cylinders to allow some of the cutting deck weight to be

transferred to the traction unit to improve traction.

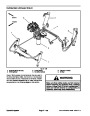

Each of the cutting decks (center, right and left) can be

raised independently with the use of three (3) switches

on the armrest console. Pressing the rear of a switch

provides an input for the TEC--5001 controller to raise a

cutting deck. The controller provides electrical outputs

to solenoids in the lift/lower manifold to allow appropri-

ate valve shift to cause a deck to raise.

When the deck switch is released, the manifold sole-

noids are de--energized and the lift cylinder and right

cutting deck are held in position.

Raise Left Cutting Deck

To raise the left deck, the rear of the left console switch

is depressed as an input to the TEC--5001 controller.

The controller provides an electrical output to solenoid

valves S1 and S2 in the lift/lower manifold. The ener-

gized solenoid valves shift to allow a passage for circuit

oil flow to the barrel end of the left deck lift cylinder.

Shifted S1 prevents oil flow from bypassing the lift cylin-

ders. Shifted S2 allows an oil path through the orifice in

manifold port C4 and to the barrel end of the left lift cylin-

der to extend the lift cylinder and raise the left cutting

deck. Oil from the extending cylinder is directed through

S3 (de--energized), out manifold port CH, to the oil filter

and then to the traction charge circuit.

When the cutting decks are in a stationary position, all

solenoids in the lift/lower manifold are de--energized. In

this position, lift/lower circuit flow bypasses the lift cylin-

dersandisdirectedthroughthelift/lowermanifold,oilfil-

ter and is then available for the traction charge circuit.

NOTE: To raise a cutting deck, the operator must be in

the operator seat.

Raise Center Cutting Deck

To raise the center cutting deck, the rear of the center

console switch is depressed. The switch signal is an in-

put to the TEC--5001 controller which provides an elec-

trical output to solenoidvalves S1and S5inthelift/lower

manifold. The energized solenoid valves shift to allow a

passage for circuit oil flow to the rod end of the center

deck lift cylinders. Shifted S1 prevents oil flow from by-

passing the lift cylinders. Shifted S5 allows an oil path to

the rod end of the front lift cylinders causing the lift cylin-

ders to retract and raise the center cutting deck. An ori-

fice in the fitting at manifold port C2 (.070) exists to

control the raise speed of the cutting deck. Oil from the

barrel end of the retracting cylinders returns to the hy-

draulic reservoir.

When the deck switch is released, the manifold sole-

noids are de--energized and the lift cylinder and left cut-

ting deck are held in position.

When the deck switch is released, the manifold sole-

noids are de--energized and the center deck lift cylin-

ders and center cutting deck are held in position.

Groundsmaster 4000--D/4010--D

Page 4 -- 17

Hydraulic System

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 10176SL, Toro Groundsmaster 30446, Toro Groundsmaster 30448, Toro Groundsmaster 4010 D |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)