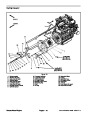

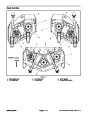

Removal (Fig. 5)

Park machine on a level surface, lower cutting

decks, stop engine, apply parking brake and remove

key from the ignition switch.

5. Align lift cylinder with lift arm. Secure lift cylinder to

lift arm with lift cylinder pin (item 3).

1.

6. Install side deck rear arm assembly (see Side Deck

Rear Arm Assembly Installation in this section).

2.

Deck Removal in Chapter 8 -- Cutting Decks).

Remove side deck from lift arm (see Side Cutting

7. If sensing plate (item 26) was removed from lift arm,

secure plate so it is rotated as far as possible toward

center of machine.

3.

Removesidedeckreararmassembly frompivothub

(see Side Deck Rear Arm Assembly Removal in this

section).

8. Positionandinstallsidecuttingdecktomachine(see

Side Cutting Deck Installation in Chapter 8 -- Cutting

Decks).

4.

Removeliftcylinderpin(item3)thatsecuresliftcylin-

der to lift arm.

9. Lubricate lift arm grease fittings after assembly is

complete.

5.

Drive out slotted roll pin (item 15) that retains lift arm

pivot shaft. Discard roll pin.

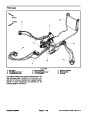

10.After assemblyiscompleted,raiseandlowerthecut-

tingdecktoverifythathydraulichosesandfittingsdonot

contact anything.

6.

Support lift arm and pull lift arm pivot shaft from lift

armandframe.Locateandremovethrustwashers(item

5)

during pivot shaft removal.

9/16”

hole

3”

x 12” (3/8” to 1/2” thick) plate steel

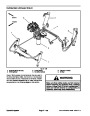

A. If pivot shaft is difficult to remove, fabricate a pull-

er as shown in Figure 7.

B. Attachpullertoendofpivotshaftwiththepictured

bolt and flat washer.

1/2”

-- 13 UNC bolt

Flat washer

C. Drivepivotshaftfromliftarmandframewithham-

mer.

7.

Remove lift arm from machine.

1”

to 1 1/8”

Installation (Fig. 5)

1.

2.

placed (Fig. 5). Slide pivot shaft into frame and lift arm

until roll pin holes in shaft and frame align.

Apply anti--seize lubricant to lift arm pivot shaft.

Positionliftarmtoframewiththrustwashersproperly

Use hammer to drive

pivot shaft from lift arm

3.

Install new slotted roll pin to secure lift arm pivot

shaft.

4.

If pivot hub was removed from pivot shaft, slide pivot

hub onto shaft. Apply Loctite #242 (or equivalent) to cap

screw threads and secure pivot hub with washer and

cap screw. Torque cap screw from 77 to 96 ft--lb (105

to 130 N--m).

Figure 7

Groundsmaster 4000--D/4010--D

Page 7 -- 7

Chassis

Product Specification

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 10176SL, Toro Groundsmaster 30446, Toro Groundsmaster 30448, Toro Groundsmaster 4010 D |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |