8.

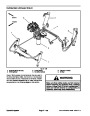

seals from wear plates.

Remove and discard back--upgaskets and pressure

1

2

3

4

9.

Turn front flange over, with seal side up.

IMPORTANT: Make sure not to damage the front

flange counter bore when removing the seals from

the front flange.

10.Carefully

remove dust seal, retaining ring, flange

washer and shaft seal from the front flange (Fig. 93).

Note orientation of seal lips during removal. Discard re-

moved seals.

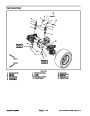

Inspection

Figure 93

3.

4.

1.

emery cloth.

Remove any nicks and burrs from all parts with

1.

2.

Dust seal

Retaining ring

Flange washer

Shaft seal

CAUTION

3

4

1

Use eye protection such as goggles when using

compressed air.

2.

pressed air.

Clean all parts with solvent. Dry all parts with com-

2

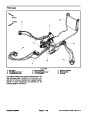

3.

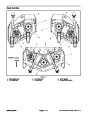

Inspect drive gears and idler gears for the following

(Fig. 94):

2

A. Gear shafts should be free of rough surfaces and

4

3

excessive wear at bushing points and sealing areas.

Scoring, rough surfaces or wear on gear shafts indi-

cates need for replacement.

Figure 94

3.

4.

1.

2.

Gear shaft spline

Gear shaft

Gear teeth

Gear face edge

B. Gear teeth should be free of excessive scoring

and wear. Any broken or nicked gear teeth must be

replaced.

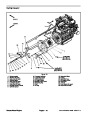

Assembly (Fig. 91)

NOTE: When assembling motor, check the marker line

on each part to make sure parts are properly aligned

during assembly.

C. Inspect gear face edge for sharpness. Sharp

edges of gears will mill into wear plates and, thus,

must be replaced.

1.

Lubricate O--rings,pressure seals, back--upgaskets

4.

Inspect wear plates for the following:

and wear plate grooves with a thin coat of petroleum jel-

ly. Lubricate all other internal parts freely with clean hy-

draulic oil.

A. Bearingareasshouldnothaveexcessive wearor

scoring.

2.

entation of seal lips during installation:

Install new seals into front flange (Fig. 93). Note ori-

B. Face of wear plates that are in contact with gears

should be free of wear, roughness or scoring.

A. Press shaft seal into front flange until it reaches

the bottom of the bore.

C. Thickness of wear plates should be equal.

Inspect front flange and body for damage or wear.

5.

B. Install flange washer into front flange and then

install retaining ring into the groove of the front

flange.

C. Install new dust seal into front flange.

Groundsmaster 4000--D/4010--D

Page 4 -- 121

Hydraulic System

Product Specification

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 10176SL, Toro Groundsmaster 30446, Toro Groundsmaster 30448, Toro Groundsmaster 4010 D |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |