Reel Removal

Reel Installation

1.

2.

3.

4.

Remove weight from cutting unit.

Remove bedbar assembly.

CAUTION

Remove front roller assembly.

Contact with the reel, bedknife or other cutting

unit parts can result in personal injury. Use

heavy gloves when installing the cutting reel.

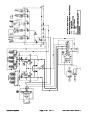

Loosen set screw and remove bearing adjustment

nut from L.H. bearing housing.

5.

L.H. bearing housing. Remove L.H. bearing housing. It

is not necessary to remove the R.H. bearing housing.

Use a hammer and punch to drive out roll pins from

1. Set cutting unit frame in a vertical position so R.H.

bearing housing is down. Install reel into R.H. bearing

housing.

6.

from the R.H. bearing housing and remove from cutting

unit frame.

Carefully slide the cutting reel with bearing and seal

2. Install L.H. bearing housing onto bearing and seal on

cuttingreel.InstallrollpinstopositionL.H.bearinghous-

ing to side plate. Secure bearing housing with screws

and lock nuts.

Inspection

3.

Place cutting unit in a horizontal position.

1.

Replace reel if diameter has decreased to the service

limit (see Reel Grinding Specifications).

4. Hit end of reel shaft with a brass hammer to make

sure that R.H. reel bearing is seated on shoulder of R.H.

bearing housing.

2.

3.

Replace reel if blades are bent or cracked.

Inspect reel shaft splined inserts and replace if worn

5.

Apply a film of grease to outside diameter of bearing

or damaged.

adjustment nut. Install adjustment nut into L.H. bearing

housing and use special spanner wrench TOR4064 to

tighten the adjustment nut approximately 1/4 turn past

first contact with the bearing.

The splined inserts are installed with thread locking

compound (Loctite 242 or equivalent). One side is

L.H. threads and the other R.H. threads (the side of

the reel with R.H. threads has an identification

groove on outer surface of flange). To remove or

install threaded spline inserts, use tool TOR4074.

Before installing inserts into reel shaft, clean all

threads and apply Loctite 242 or equivalent to

threads. Install and tighten insert to a torque of 75 -

Note:

Reel bearings do not require pre--load. Over

tightening reel bearing adjustment nut will damage reel

bearings.

6. Loosen the bearing adjustment nut and then tighten

adjustment nut to a torque of 15 - 17 in--lb (17 - 19

KgCm).

85

ft-lb (10.4 - 11.8 KgM).

4.

bearings:

Inspect reel bearings and seals. To replace seals and

7.

alent) to threads of set screw. Tighten set screw to

secure bearing adjustment nut.

Applythreadlockingcompound(Loctite242orequiv-

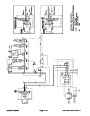

A. Use a bearing puller tool to remove the bearings

fromthereelshaft.Removetheseals.NOTE:Ifbear-

ings and seals are removed from reel shaft, discard

and replace removed components.

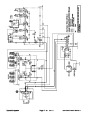

A. For socket head set screw (Fig. 34), tighten set

screw one-half turn beyond initial contact minimum.

B. For square head set screw (Fig. 35), tighten set

screw to a torque of 25 - 35 in-lb (29 - 40 KgCm).

IMPORTANT: The seals should be installed so

the metal side of the seal is toward the bearing

location.

8.

9.

Install front roller assembly.

Install bedbar assembly.

B. Install new seals on the reel shaft pressing on the

steel surface of the seal. Make sure seals are

installed square to shaft and are pressed fully to reel

shaft shoulder.

10.

Apply anti-seize lubricant to internal splines of

splined couplers.

C. Pack bearings with No. 2 general purpose grease

before installing. Install bearings on reel shaft by

pressing equally on inner and outer bearing race.

Bearings should bottom on reel shaft shoulder.

11. Install weight assembly to cutting unit.

D. Apply a film of grease to outside diameter ofseals

and bearings.

Cutting Units

Page 7 - 22 Rev. E

Reelmaster 6500-D/6700-D

| Categories | Lawn Mower Manual, Toro Lawn Mower Manual |

|---|---|

| Tags | Toro Reelmaster 6500-D, Toro Reelmaster 6700-D |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Product Type | Walk Behind Mower |

| Engine Manufacturer | Toro |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)