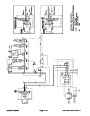

Inspection of Cutting Reel (Fig. 27)

Inspect reel bearings to insure that they spin freely

and have minimal axial play. The bearing balls must be

free of deformation and scoring.

Assembly of Cutting Reel (Fig. 27)

1.

1. If seals and/or bearings were removed from reel

shaft, discard removed components and replace.

2.

Make sure that the two (2) retaining rings are fully

2.

Inspectthereelshaftasfollows.Ifreeldamage isde-

seated into the grooves on the cutting reel shaft.

tected, replace reel.

3.

If bearings and seals were removed from reel shaft:

A. Check the reel shaft for bending and distortion by

placing the shaft ends in V--blocks.

A. Make sure that bore of seals are clean with no

grease or lubricant applied to ID of seal.

B. Check the reel blades for bending or cracking.

IMPORTANT: The

grease

seal

should

be

installed so the metal side of the seal is toward

the bearing location.

C. Check the service limit of the reel diameter (see

Preparing a Reel for Grinding in this section).

3.

cessive wear or distortion. Replace inserts if damage is

evident.

Check the threaded inserts in the reel shaft for ex-

B. Pressgreasesealsontoreelshaftwithmetalside

orientated toward bearing location. Final position of

sealshouldbeflushto0.060”(1.5mm)awayfromre-

taining ring on reel shaft. Do not force seal against

retaining ring. Seal must be perpendicular to reel

shaft after installation.

A. The threaded inserts are installed with thread

locking compound (Loctite #242 or equivalent). One

insert has LH threads and the other RH threads. The

insertwithLHthreadshasanidentificationgrooveon

the flange face. A groove on the reel shaft approxi-

mately 2”fromtheendidentifies thereelendthathas

LH threads (see illustration in Fig. 27).

C. Pack replacement reel bearings with Mobil High

Temperature HP grease (or equivalent).

D. Press grease packed bearings fully onto reel

shaft.Bearingsshouldbottomonreelshaftshoulder.

Press equally on inner and outer bearing race when

installing bearings onto reel shaft.

B. To remove or install threaded spline inserts, use

correct spline insert tool (see Special Tools).

C. To install spline insert into cutting reel, clean

threads of insert and cutting reel shaft. Apply Loctite

4. Pack bore of reel shaft with Mobil High Temperature

HP (or equivalent) grease.

#242

(or equivalent) to threads of insert, thread in-

sertinto reelshaft andtorque from 85 to95 ft-lb (115

to 128 N--m).

Reelmaster 6500--D/6700--D

Page 7.2 -- 27 Rev. E

DPA Cutting Units

| Categories | Lawn Mower Manual, Toro Lawn Mower Manual |

|---|---|

| Tags | Toro Reelmaster 6500-D, Toro Reelmaster 6700-D |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Product Type | Walk Behind Mower |

| Engine Manufacturer | Toro |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)