Groomer Reel Service

Inspect groomer reel blades frequently for damage and

wear.Straightenbentbladeswithapliers.Eitherreplace

worn blades or reverse the blades to put the sharpest

blade edge forward (Fig. 11). Blades thatare rounded to

the midpoint of the blade tip must be reversed or re-

placed for best groomer performance.

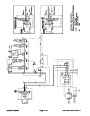

5. Ifgroomer reelisequippedwithbroomerkit(Fig.13),

positionbroomerbrushestoreelbladesandsecurewith

straps. Straps should be positioned between blades

1--2, 14--15, 28--29 and 41--42. Pull straps tight and cut

off strap extension approximately 1/4” (6 mm) beyond

retainer.

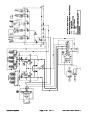

Disassembly (Fig. 12)

4

1

1.

Park machine on a clean and level surface, lower

cutting units completely to the ground, stop engine, en-

gage parking brake and remove key from the ignition

switch.

2.

er Reel Removal in this section).

Remove groomer reel from cutting unit (see Groom-

5

3.

o--ring from non--drive end of groomer shaft

Remove excluder seals from groomer reel. Remove

3

GROOMER

ROTATION

4.

remove straps and broomer brushes from reel.

Ifgroomer reelisequippedwithbroomerkit(Fig.13),

5.

Remove lock nut from either end of the shaft (Fig.

12).

2

6.

needed, remove second lock nut from shaft.

Remove spacers and blades from groomer shaft. If

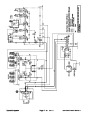

Figure 11

1.

2.

3.

Groomer blade (D shaft)

Blade (hex shaft)

Location mark

4.

5.

Sharp edge

Dull (rounded) edge

Assembly (Fig. 12)

1.

first spacer and then first blade on shaft.

Install lock nut on drive end of groomer shaft. Place

200

(23

to 250 in--lb

to 28 N--m)

Note:

Early production groomer shafts were hex

shaped. Later production shafts have a D--shaped

cross--section. When installing groomer blades on ear-

lier, hex shaped shafts, rotate location mark on each

installed blade one flat of the shaft, either in a clockwise

or counterclockwise direction. The direction of location

mark rotation must remain constant on the shaft.

2

1

3

4

2.

making sure that all blades are separated by a spacer.

Alternately install remaining spacers and blades

5

CENTERED ON SHAFT

3.

spaceronshaftandthenthreadsecondlocknutontothe

shaft. Center blades on shaft with lock nuts.

When all blades have been installed, place final

4.

Using wrench on shaft flats to prevent shaft from

turning, torque second lock nut from 200 to 250 in--lb

to 28 N--m). After torquing lock nut, spacers should

(23

4

4

5

1

3

2

not be free to rotate and groomer blades should be cen-

tered on shaft.

Figure 12

1.

2.

3.

Groomer reel shaft

Groomer blade (42 used)

Spacer (43 used)

4.

5.

Lock nut (2 used)

Excluder seal

DPA Groomer

Page 7.3 -- 12 Rev. E

Reelmaster 6500--D/6700--D

| Categories | Lawn Mower Manual, Toro Lawn Mower Manual |

|---|---|

| Tags | Toro Reelmaster 6500-D, Toro Reelmaster 6700-D |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Product Type | Walk Behind Mower |

| Engine Manufacturer | Toro |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)