6.

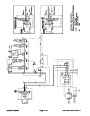

and each cutting unit side plate (Fig. 20).

Position a plastic washer (item 16) between bedbar

CAUTION

7.

Install the bedbar pivot bolt assemblies. Make sure

Contact with the reel, bedknife or other cutting

unit parts can result in personal injury. Use

heavy gloves when handling the bedbar.

that plastic washers are not caught on the threads of the

pivot bolts. Tighten each bedbar pivot bolt from 27 to 33

ft--lbs (37 to 44 N--m).

8.

Tighten both lock nuts (item 19) until outside metal

6.

7.

ings (item 14) in side plates for wear or damage. Re-

move bushings and replace if necessary.

Remove bedbar assembly from cutting unit.

washer just stops rotating. Do not over tighten the lock

nuts as this can distort the side plates and affect reel

bearing adjustment. The plastic washer between the

bedbar and side plate should be loose.

Inspect flange bushings (item 15) and rubber bush-

9.

er assembly until the adjuster spring is fully com-

pressed, then loosen lock nut 1/2 turn.

Tightenthe lock nut(item 13) on each bedbar adjust-

Bedbar Installation (Fig. 19)

1.

If rubber bushing was removed from either cutting

unit side plate, install a new bushing. The bushing

should be installed flush with the inside of the side plate

(Fig. 20).

10.Adjust

Manual).

cutting unit (see Cutting Unit Operator’s

11.

Install cutting unit to machine.

2.

If removed, install the flange bushings (item 15) with

flangefacingoutward.Applyantiseizelubricanttoinside

of flange bushing.

Antiseize

Lubricant

1

8

7

3.

Apply antiseize lubricant to the bedbar threads and

the shoulder area of each bedbar pivot bolt.

4.

washer (item 16) onto each bedbar pivot bolt.

Slide one metal washer (item 17) and one plastic

CAUTION

Contact with the reel, bedknife or other cutting

unit parts can result in personal injury. Use

heavy gloves when handling the bedbar.

3

6

4

4

5

2

Figure 20

5.

top ofeach bedbar arm isbetween washer (item 11)and

adjuster screw flange (item 10).

Position bedbar into cutting unit. Make sure that the

1.

2.

3.

4.

Cutting unit sideplate

Rubber bushing

Flange bushing

5.

6.

7.

8.

Washer (metal)

Bedbar

Bedbar pivot bolt

Lock nut

Washer (plastic)

Reelmaster 6500--D/6700--D

Page 7.2 -- 19 Rev. E

DPA Cutting Units

Product Specification

| Categories | Lawn Mower Manual, Toro Lawn Mower Manual |

|---|---|

| Tags | Toro Reelmaster 6500-D, Toro Reelmaster 6700-D |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Product Type | Walk Behind Mower |

| Engine Manufacturer | Toro |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |