TEST NO. 3: Cutting Unit Drive Circuit Pressure

Note:

Thefrontcutting unitdrivecircuitisprotectedby

reliefvalveR1andtherear circuitbyreliefvalve R2.See

Hydraulic Flow Diagrams at the beginning of this chap-

ter.

2

1

1.

Make sure hydraulic oil is at normal operating tem-

perature by operating the machine for approximately 10

minutes.

2.

the cutting units lowered and off. Make sure engine is

off.

Make sure machine is parked on a level surface with

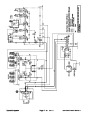

Figure 15

2.

CAUTION

1.

Test Port G1 (front)

Test Port G2 (rear)

Prevent personal injury and/or damage to equip-

ment. Read all WARNINGS, CAUTIONS, and Pre-

cautions for Hydraulic Testing at the beginning

of this section.

3.

Install a 5000 PSI gauge with extension hose onto quick

disconnect fitting in port G1 or G2 (Fig. 15).

Raise hood to get access to hydraulic test fittings.

4.

Make sure Mow/Backlap valve MD1 or MD2 is in the

“Mow” position.

Set reel speed control FC1 or FC2 to position 5.

5.

Make sure cutting units are completely lowered and

engine is OFF.

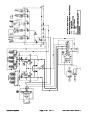

Figure 16

To check the front circuit, insert a block of wood be-

tweencuttingunitreelbladesandfrontcrosstubesof

any two-front cutting units to prevent the reels from

turning (Fig. 16). Two cutting unit reels must be

blocked to exceed the 3000 PSI front cutting unit cir-

cuit relief valve R1.

7.

to ENABLE. Move ”Lower- Mow/Raise” lever forward to

engage cutting units, then look at the gauge.

While sitting on seat, move ”Enable/Disable” switch

GAUGE READING (front): 3000 +/- 50 PSI.

GAUGE READING (RM 6500--D rear):

2000

+/- 50 PSI.

GAUGE READING (RM 6700--D rear):

+/- 50 PSI.

To check the rear circuit, insert a block of wood be-

tweencuttingunitreelbladesandfrontcrosstubesof

any two-rear cutting units to prevent the reels from

turning (Fig. 16). Two cutting unit reels must be

blocked to exceed the rear cutting unit circuit relief

valve R2.

3000

8.

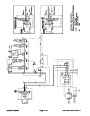

Stop the engine. If pressure is too high, remove cap

on relief valve R1 or R2 and adjust screw to get correct

pressure(seeAdjustManifoldReliefValves).Ifpressure

is too low, check for restriction in pump intake line. Re-

move cap from relief valve R1 or R2 and adjust screw to

get correct pressure. If pressure is still too low, pump or

reelmotorshouldbesuspectedofwear,damageorinef-

ficiency.

6.

Sit on the seat and start the engine. Move throttle to

full speed (3200 RPM).

WARNING

Note:

Normal operating pressure when mowing is

approximately 500 to 600 PSI. per cutting unit. The front

circuit should operate at 1500 to 1800 PSI. and the rear

circuit should operate at 1000 to 1200 PSI. for 6500-D

and at maximum circuit pressure for 6700-D.

Keepawayfromallreelsduringtesttopreventper-

sonal injury from rotating reel blades.

Reelmaster 6500-D/6700-D

Page 4 - 39 Rev. B

Hydraulic System

| Categories | Lawn Mower Manual, Toro Lawn Mower Manual |

|---|---|

| Tags | Toro Reelmaster 6500-D, Toro Reelmaster 6700-D |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Product Type | Walk Behind Mower |

| Engine Manufacturer | Toro |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)