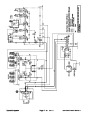

Disassembly (Fig. 28)

Position the pump into a protected jaw vise, clamping

6. Lift backplate straight up off shaft and housing (47).

Remove valve plate (22) from backplate or from rotating

kit assembly (6) still in housing.

1.

onto the outer portion of the flange, with the cap screws

up. Mark the relationship of the working ports (for reas-

sembly identification) tothe servo control assembly with

a scribe. Remove the four screws (19 & 20).

7. From backplate, remove dump valve (42), and relief

valve assemblies (17).

Note:

Mark the relief valve in relationship to the cavity

2.

up off backplate (24) and shaft (25). Remove the outer

gerotor (36).

Lift the charge pump adapter assembly (32) straight

it was removed, for reassembly purposes.

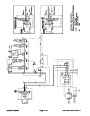

Backplate Inspection:

¯ Check the bearing (48) (press fit) in backplate. If

needles remain in cage, move freely, and bearing is

set to the dimension shown, removal not required

(Fig. 30).

3.

Remove O-ring (26) from charge pump adapter.

4.

&

Remove the inner gerotor and coupler assembly (35

40) from the drive shaft.

5.

valve from the charge pump adapter.

Remove the outer gerotor and charge pump relief

¯ Check roll pin (49) in backplate. If tight and set to the

dimension shown, removal not required (Fig. 30).

Charge Pump Inspection:

¯

¯

Check the coupler (40) and gerotors (35 & 36) for

wear, cracks, or damage.

Inspect the charge pump relief valve seat inside the

charge pump adapter. The seat should be smooth

and free of burrs and other damage.

¯

¯

Inspect the charge pump relief valve spring (58).

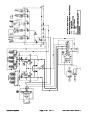

Check the bearing (56) (press fit) in charge pump

adapter. If needles remain in cage, move freely, and

bearingissettothedimensionshown,removalnotre-

quired (Fig. 29).

Figure 30

8.

backplate.

Remove housing gasket (11) from housing and/or

¯

Check the gerotor pocket inside the charge pump

adapter.The gerotor pocket should notbe excessive-

ly scored.

9. Withpumpstillinvise,removethesixcapscrews(21)

retaining the servo control assembly (34). Remove the

control assembly and control housing gasket (50) from

the housing. Remove orifice plates (37 & 38), noting

location for reassembly. Remove nut and lock washer

(27

& 28) and remove control arm (33). Note position of

control arm for reassembly.

10.

To remove rotating kit assembly (6) from housing,

firstremove pumpfromvisewhileholdingtherotatingkit

assembly in position. Lower pump so that the shaft end

(flange end) isup.Setthe rearofhousing onto tablewith

housing flat and rotating kit assembly at rest on table.

(Hole in table, for protruding shaft, is required.) Lift and

remove the housing and shaft from rotating kit assem-

bly, and camplate.

11.

Remove camplate (14) from rotating kit assembly.

Remove piston follower (8) from camplate.

Figure 29

Reelmaster 6500-D/6700-D

Page 4 - 55

Hydraulic System

| Categories | Lawn Mower Manual, Toro Lawn Mower Manual |

|---|---|

| Tags | Toro Reelmaster 6500-D, Toro Reelmaster 6700-D |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Product Type | Walk Behind Mower |

| Engine Manufacturer | Toro |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)